Note: the information contained in this fact sheet is for general education and information purposes only. Proper selection of respiratory protection must be completed by a qualified individual who has performed a full hazard analysis of the worksite and tasks. Images are for demonstration purposes. CUPE does not make general endorsements or recommendations for any brand of personal protective equipment.

- Download a printable copy of the fact sheet Respiratory Protection.

Protecting workers from respiratory hazards

Many CUPE members work in occupations that put them at risk of exposure to respiratory hazards. These hazards include oxygen-deficient atmospheres, airborne contaminants (including mists, fumes, dusts, or other gasses that may be toxic), or biological contaminants that may harbour any number of infectious diseases. Workplaces that include confined spaces may expose workers to a number of these respiratory hazards at once.

When it comes to controlling respiratory hazards, a hierarchy of controls must always be considered with hazards first being removed or controlled by a permanent engineered solution before considering policies, procedures and personal protective equipment such as respirators. Respiratory hazards can often be removed using engineering methods such as mechanical ventilation or isolation. Personal protective measures should only be used as a last resort, where the hazard cannot be removed.

Employers that have respiratory hazards at the worksite need to have a written respiratory protection plan developed by a competent individual. Employers must also provide adequate employee training, including respiratory hazards identification, proper respirator selection and use, and emergency procedures.

Types of respiratory protection

Types of respiratory protection

There are a number of respiratory protection products on the market. They do not all offer the same level of protection.

FACE MASKS

A face mask is a loose-fitting, disposable device that creates a physical barrier between the mouth and nose of the person wearing the mask and potential contaminants in the immediate environment. There are several common types, most notably dust masks and surgical masks.

When worn properly, a face mask is only meant to help block large-particle dust or droplets (splashes, sprays or splatter) from reaching your mouth and nose. Face masks are also beneficial because they help reduce other people’s exposure to saliva and respiratory secretions from the person wearing the mask.

However, it must be clearly understood that by design, a face mask will not filter or block small particles in the air that may be transmitted by coughs, sneezes or certain medical procedures. Face masks do not provide complete protection from viruses or bacteria and other airborne contaminants because of the loose fit between the surface of the face mask and your face.

Finally, face masks are meant to be disposable, and not intended to be used more than once. If a mask is damaged or soiled, or if breathing through the mask becomes difficult, it should be removed and discarded safely according to required procedures, and replaced with a new one.

RESPIRATORS

The two main types of respirators are supplied-air respirators (SARs) and air-purifying respirators (APRs). The selection of the type of respiratory protection required will depend on the hazards present in the work environment.

Supplied-air respirators

Some workplace atmospheres contain concentrations of hazardous substances that put workers in immediate danger.

Known as an “Immediately Dangerous to Life or Health” (IDLH) atmosphere, it poses an immediate threat to life and can cause irreversible adverse health effects, or can impair a person’s ability to escape[i]. In workplaces that contain this type of hazard, air must be continuously supplied to the worker. There are two types of systems that supply air: self-contained breathing apparatus (SCBA) and continuous flow systems.

SCBA systems are designed for short-term work (such as rescue or short entrance into a IDLH atmosphere) and have high-pressure tanks to supply clean air to the worker, a regulator to control the pressure and a respiratory inlet that is composed of either a tight fitting half mask or face shield, or a looser fitting hood or helmet (see image[ii]).

Continuous flow systems are designed for longer work in controlled or limited work environments, such as research laboratories or paint shops. In these systems, the worker is connected to a continuous air supply through a hose that is connected to a large tank or external supply. Similar to the SCBA system, the worker wears either a tight-fitting mask or a loose hood or helmet system. Continuous flow systems can also be fitted to full-capsulation body suits.

Air-purifying respirators (APRs)

Probably the most familiar type of respirators are particulate filters. These filters work by passively filtering out harmful particles as air passes through a filtering material. They come in several styles:

- Quarter-mask (covering the nose and mouth)

- Half-face mask (covering from the nose to below the chin), and

- Full-face piece (covering from above the eyes to below the chin).

Note: APRs are not adequate for use in an IDLH atmosphere.

Common particulate respirators seen by CUPE members are partial-face “N95” masks. Air Purifying, particulate filtering respirators are all rated with a letter and a number:

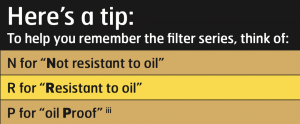

- N-Series filters are designed to be used for protection against solid and water-based particles, but should not be used where oil aerosols are present

- R-Series filters are designed to be used for protection against all particles, and are designed for exposure to oil aerosols, but can only be used for up to 8 hours

- P-Series filters are designed to be used for protection against all particles, and are designed for exposure to oil aerosols, but can be used longer than the R-series

Due to the way small particles behave, extremely small particles and large particles are more easily captured by respiratory filter material. For this reason, testing and rating of respiratory masks are completed by determining the percentage of 0.3 μm size particles as they are the most likely to pass through the filter material.

For example:

- A mask rated 95 (i.e. N95) is 95% filter efficient when tested with ~0.3 μm test substance

- A mask rated 99 (i.e. R99) is at least 99% filter efficient when tested with ~0.3 μm test substance

- A mask rated 100 (i.e. P100) is at least 99.97% filter efficient when tested with ~0.3 μm test substance

Chemical cartridge respirators

These respirators have a chemical cartridge and may also be used in combination with a particulate filter. The chemical cartridge contains a substance that has the ability to collect molecules of another substance by a process known as sorption. A combination of filters can provide protection against different kinds of contaminants in the air[iv]. It is critical that the correct filter is selected.

For simplicity of identification, the industry has developed a colour code that identifies the type of filtration. Some examples are:

- White = Acid gas

- Black = Organic vapors

- Yellow = Acid gas and organic vapors

- Green = Ammonia or methylamine

Powered air-purifying respirators (PAPRs)

These respirators use the same filtration system as other respirators described above but also include a fan to draw air through the filter to the user. They are easier to breathe through but rely on a battery to work properly.

Limits of Use

All respirators have a limited time for use. Particulate filters capture particles, and actually become more efficient until they become too clogged and breathing becomes difficult. Chemical cartridges also become saturated, and will stop working, allowing contaminated air to pass.

Note: It is critical to read the manufacturer’s instructions on how often a respirator or filter needs to be changed.

Fit-testing

A respirator will not protect a worker if it does not fit properly. All respirators that are designed to fit snuggly to the face (known as “tight fitting”) must be properly fit-tested to that worker to ensure that they are getting the correct size. A “fit test” is a procedure that physically tests the seal between the respirator’s face piece and a worker’s face. It must be performed using the same size and model of respirator the worker will actually be using on the job. Fit testing should be performed every year to ensure that people’s facial structure has not changed as a result of a significant weight change.

There are two basic methods of fit testing: qualitative and quantitative.

Probably the most common of the two methods, and frequently used for half-mask respirators, qualitative fit testing is a pass/fail test method that uses a worker’s sense of taste or smell, or a reaction to an irritant, to detect leakage around the respirator. Whether the respirator passes or fails the test is based simply on the worker detecting leakage of the test substance into their respirator.

Quantitative fit-testing uses a machine that creates a negative pressure to measure the actual amount of leakage into the respirator, and is not dependent on worker reaction. During the testing, the respirators are fitted with a probe attached to the respirator that will be connected to the machine by a hose. This testing can be used for any style of tight-fitting respirator.

Note: To ensure a tight fit, workers must be clean shaven, as even a couple days of facial hair growth can compromise the seal.

Finally, fit-testing determines that workers are medically able to wear a tight-fitting respirator. Alternative respiratory protection is available for workers who need accommodations for a non-tight fit model (hood or helmet).

- Download a printable copy of the fact sheet Respiratory Protection.

[i] Canadian Standards Association Standard CSA Z1006-10, Management of work in confined spaces